Key Features

- Non-contact design: Eliminates mechanical wear, ensuring long lifespan and maintenance-free operation.

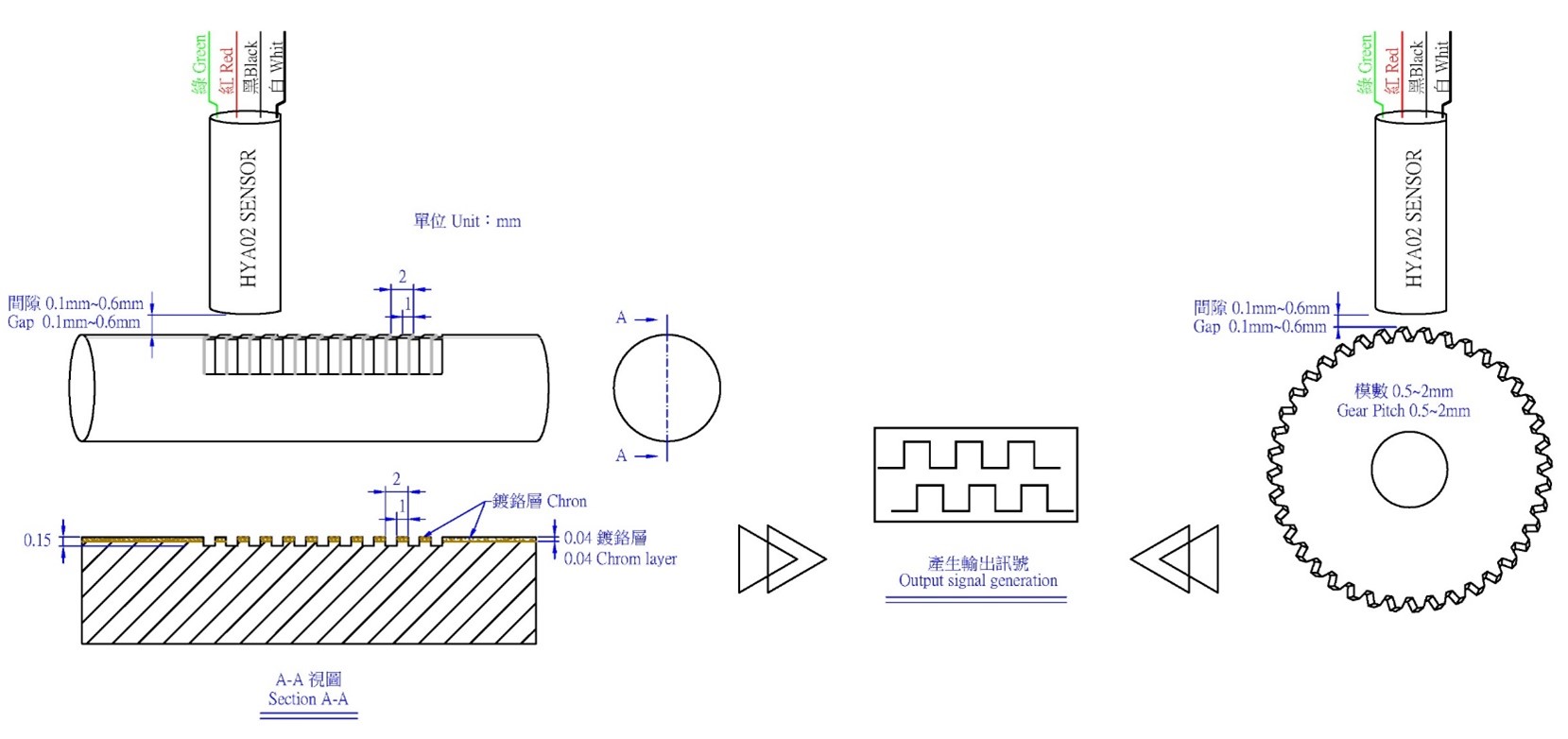

- Compact and easy to install: Ideal for equipment with limited space; installation gap ranges from 0.1 to 0.6 mm.

- High sensitivity: Detects even minimal changes in magnetic fields.

- Rapid response: Supports relative motion speeds up to 15 m/s with real-time signal output.

- Stable and robust: Engineered plastic housing resists environmental interference, ensuring reliable performance.

- High resolution: Standard resolution of 2 mm, upgradeable to 1 mm or 0.5 mm with external signal processing.

Technical Specifications

- Operating voltage:DC 12V

- Operating current:24mA

- Maximum linear speed:15m/s

- Output waveform: Dual-phase 90° phase-difference digital square wave (quadrature signal)

- Resolution: 2 mm (adjustable to 1 mm or 0.5 mm via controller)

- Operating temperature: -10°C to 85°C

- Sensing gap: Up to 0.6 mm

- Compatible gear module:0.5~2 mm

Advantages Comparison:

HYA02 SENSOR vs. Traditional Encoder/Linear Scale

| Item | HYA02 SENSOR | Traditional Encoder/Linear Scale |

|---|---|---|

| Price |

✅Low cost, highly economical

|

❌High cost, expensive to replace

|

| Installation Flexibility |

✅Easy installation, minimal space required

|

❌Requires precise alignment and ample space

|

| Durability |

✅Non-contact design, maintenance-free

|

❌Contact type or prone to dust interference

|

| Travel Distance |

✅Unlimited travel distance

|

❌Limited by fixed measuring range

|

| Application Flexibility |

✅Suitable for various automation equipment

|

❌Must be paired with specific drive/control systems

|

Installation & Usage Guidelines

- Align the sensing surface perpendicular to the gear tooth surface, maintaining a 0.1–0.6 mm gap.

- Avoid using sharp objects or screws for mounting; flat clamping is recommended to secure the sensor.

- The target object should have a height difference of at least 0.15 mm. Its surface must be smooth and may be coated with a non-magnetic material, such as chrome.

- Ensure proper alignment between the sensor and the target to maintain stable and accurate signal output.