Why Switch from Manual Boosting?

Traditional boost setup relies on manual adjustment, leading to:

- Ineffective boosting

- Accumulator damage

- Poor product consistency

Smart Boost Advantages

- Auto-activation at mold fill completion

- 100% effective boosting

- Reduced human error

- Extended accumulator life

- Simple ON/OFF operation

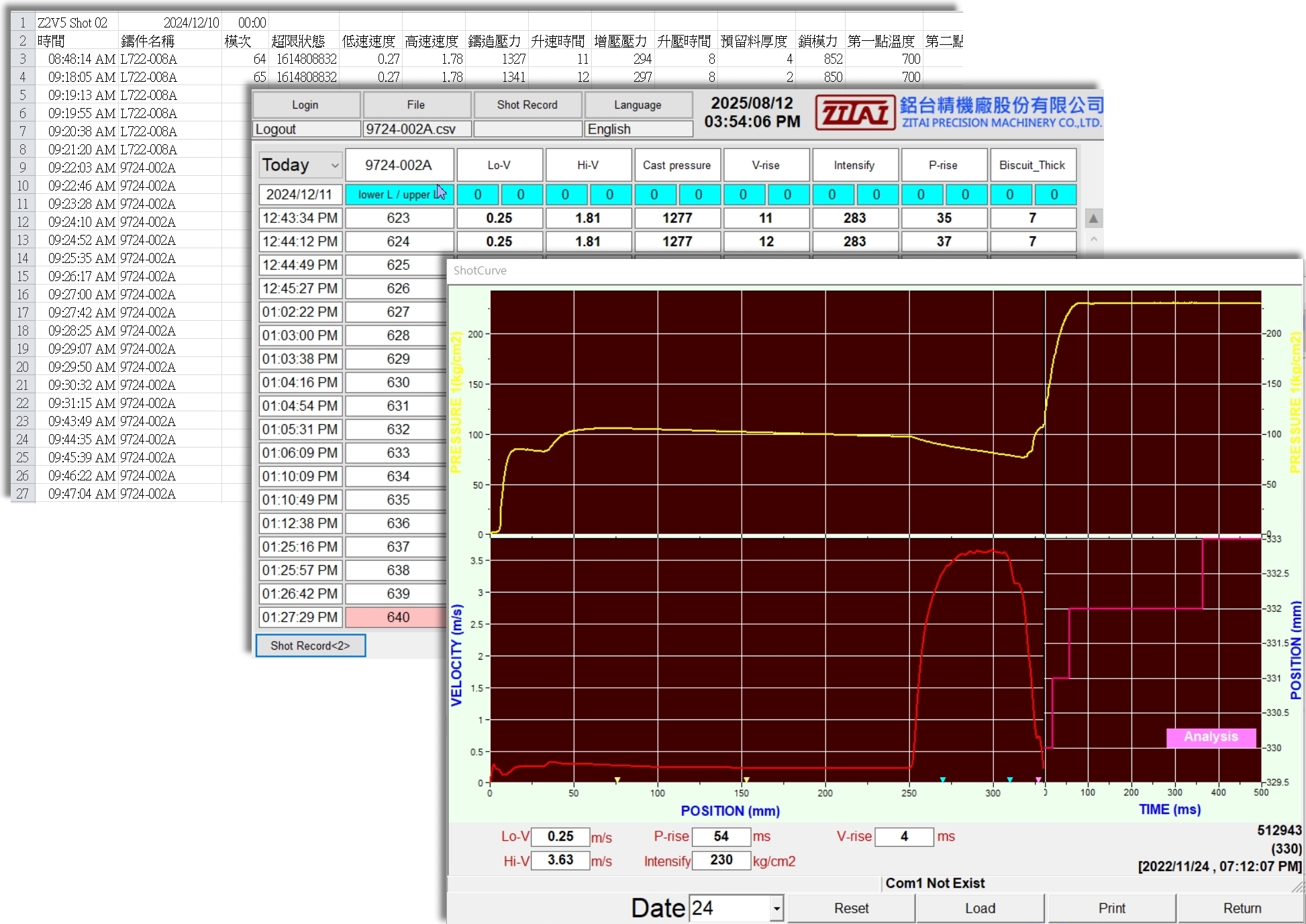

Visualized Process & Smart Monitoring

When paired with an industrial PC (e.g., S6-CPU), AP-105 / S-105 displays real-time injection curves:

- Real-time cursor analysis (time/position)

- Inflection point detection

- Peak pressure and speed analysis

- Curve zooming for detailed segment analysis

- Auto backup log system with up to 31-day circular storage

- Exportable to Excel / CSV format for easy analysis and audit tracking

- Integrated data and graphics for truly digital production management